Train Monitoring

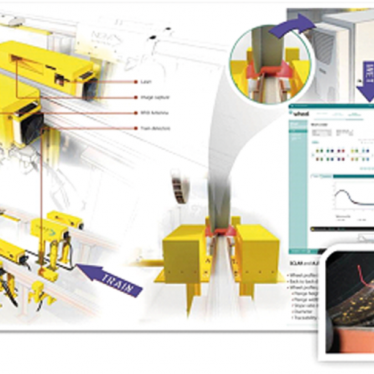

These systems are mainly designed for rolling stock inspection, such as truck wheels, brake shoes and pads, bogie components, couplers, safety appliances, and undercarriage structural components. They are usually installed under, along, and over railroad tracks. We supply wheel diameter measurement systems, wheel clearance measurement systems, hot axle box detection (HABD) and flat wheeldetection (FWD) systems, spring test press and handheld devices for railway networks.Wheel Profile and DiameterThe wheel profile and diameter is measured in real time using a combination of lasers and video cameras. Mounted wayside in the track area, the system acquires all major wheel parameters. System analysis and reporting software provides wheel performance trending and predictive identification of faulty components.

Automatic Wayside Wheel Surface Inspection System

This system is designed to inspect wheel tread surface and flange area at normal track speeds. This system offers visual inspection of complete wheel tread and flange surface using optical imaging and laser scanning.

Hot Axle Box Detector (HABD)

The system monitors the axle box and the brake temperature of coaches that cross the installation site at speeds of up to 500km/h. The system reports abnormal findings in the form of various configurable alerts to the control room. The low-height infrared scanners of the system are installed in a hollow sleeper at the tracks.

Flat Wheel Detector (FWD)

Wheels of the railway vehicles are subject to extreme stresses and strains, which inevitably lead to wear and tear. The flat wheel detection system uses precision fiber-optic technology to detect off-center wheels and flat wheel sections of coaches with wheel loads of up to 30t. It is designed as a stand-alone system or as a companion system to the HABD system. In addition to the wheel status, FWD can also report ballast status, train weight and overloads.

Automatic Brake Inspection Systems

The rail wheel and in particular the brake and its interaction with the wheel represent a decisive factor in the sphere of safety and quality of railway transport. There is the necessity to systematically check the decisive risk factors and in particular the brake status. The wayside measurement system is designed to inspect the brake shoes, brake pads and brake disks at track speeds. This system uses a multi-camera high-speed imaging unit to take multiple images for inspection and measurement.

Weighing Systems

Weighing system is a dynamic system designed for the weighing of railcars with solid or liquid loads. The precise system offers train and track operator's accurate weighing data, which allows them to avoid the potential hazards of an overloaded or unequally loaded railcar. Basic functions of the weighing system include the acquisition and monitoring of the railcar weight, and printout and storage of weighing data.

Track and Infrastructure Monitoring

We supply automatic railway inspection systems that combine precise defect detection with high processing speed. There is no limit on scheduled rail traffic as these systems provide regular and economic track inspections. Damages are detected very early, making it possible to substantially extend the lifecycle of tracks through preventive measures.These systems are used for inspecting the track including the rail, fasteners, ties, Joint, etc. We supply vehicle installed systems for rail profile measurements, track gauge and cross-level measurements. Also, we supply rail and track imaging systems.Our products include:

Rail Profile Measurement & Switch Evaluation

Flatness of the Rail and Welding Measurement

3rd Rail Position Check

Rail Check, Joint Check, Head Check, Crack Check

Vegetation Check

Manual Track Measuring Device

Soil Inspection

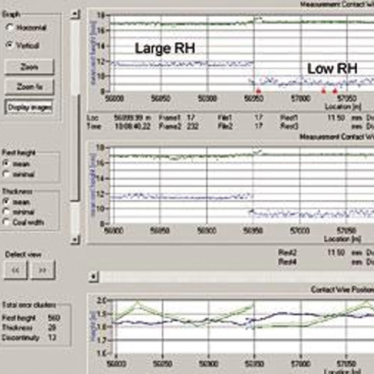

Contact Wire Inspection

Wire Inspection is carried out using an automatic measurement system which determines the thickness or the remaining height of one or more parallel contact wires at high speed.

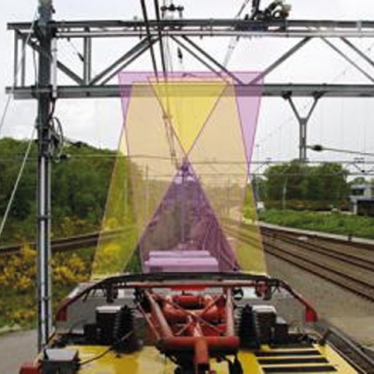

Catenary Inspection System

Catenary inspection is carried out using an automatic inspection system which inspects the catenary and catenary cross span at high speed. Automatic detection of defects by image processing including loose or missing screws, split cables and damaged components are routinely performed. Image recording of droppers, messenger wire, contact wire, shunt straps and clamps are the aspects of the measurements.

Pantograph Contact and Condition

We supply a special pantograph for testing all the parameters referred to the overhead electrical line. The system comprises a video camera to record the testing steps, a DVD system to record the images and a monitor located on the driver cab to display the images.

Intelligent Maintenance of Railway Tracks

Integrated Wheel-set Wear Management

This is a knowledge-based management system that is developed for the day-to-day management and long-term planning of wheel set maintenance. All data and information captured by the measurement tools and systems are stored, processed and presented through a single online application, assisting the optimization of wheel-set life-cycle management.

Integrated Maintenance Management of Lubricated Equipment

This provides the user with the ability to collate and manage all diagnostics that are obtained from oil and grease analysis from different laboratories to improve and optimize the maintenance of rolling stock assets. This system provides a level of oil and grease analysis and asset management at an international level and works with reputable laboratories to provide a high quality service. All results from lubricant analysis are stored and managed through the application, including appropriate photos for each oil sample. This provides the user with a powerful tool for maintenance planning of the complete fleet.

Maintenance In Motion (Intelligent Diagnostics)

An advanced system that assesses the condition of rolling stock assets such as gearboxes, doors, traction motors, drive shafts and bearings. The system acquires, stores and analyses all monitoring data from individual assets, generating diagnostic results and detecting failure symptoms long before the potential failure occurs.

Performance In Motion (Smart Logs Management)

This provides the client with a fully configurable alarm management system that acquires, manages and classifies data and alerts from multiple subsystems across multiple fleets. The system not only filters and categories alerts, but classifies and priorities alarm severity and can distinguish between useful information for the service operator and for the maintainer. In this way, the maintainer receives information necessary for asset maintenance, whilst the operator receives useful information with regards to the availability and reliability of their assets. Recommended maintenance actions are produced and can be modified and recorded to provide a feedback for any necessary action.

Asset Management In Motion

This gives the user the ability to have a complete control of rolling stock assets, their ID and location and their operational and maintenance history. This provides a base from which maintenance plans can be generated and from which alerts are generated to forewarn over-maintenance or under-maintenance of assets.